Overview

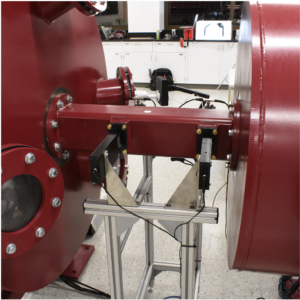

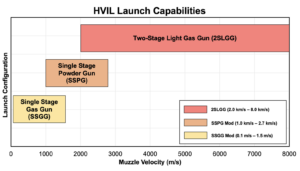

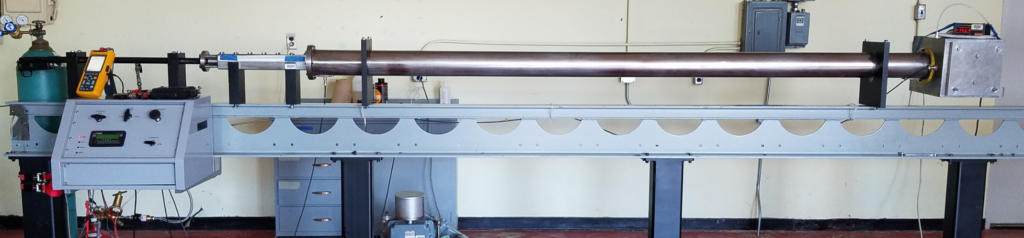

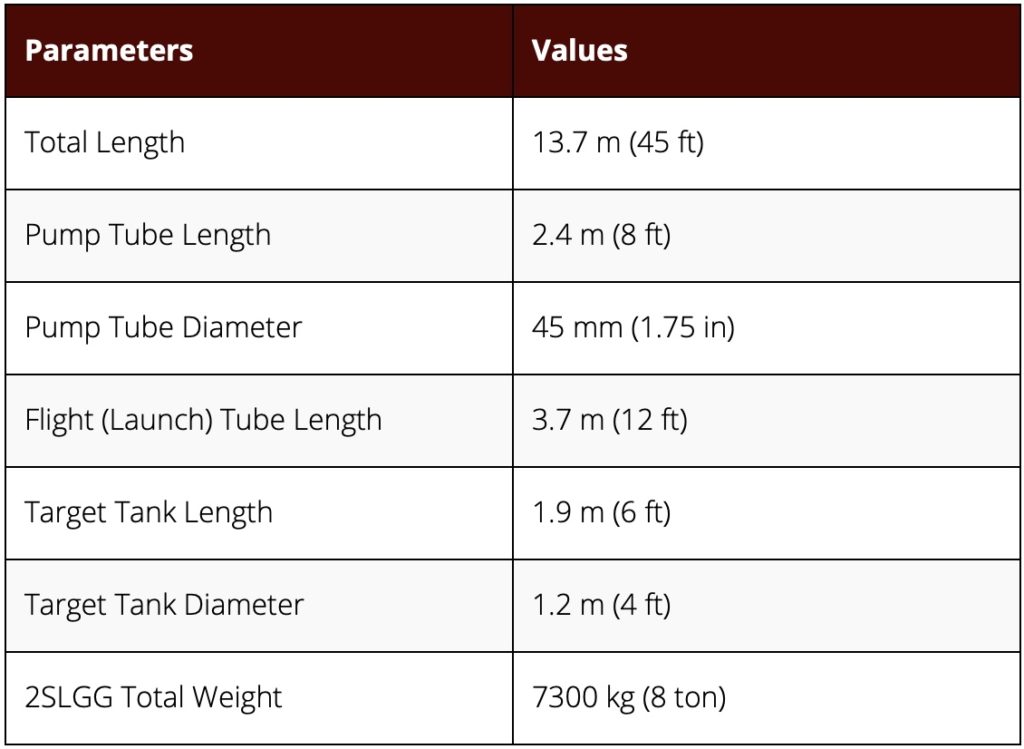

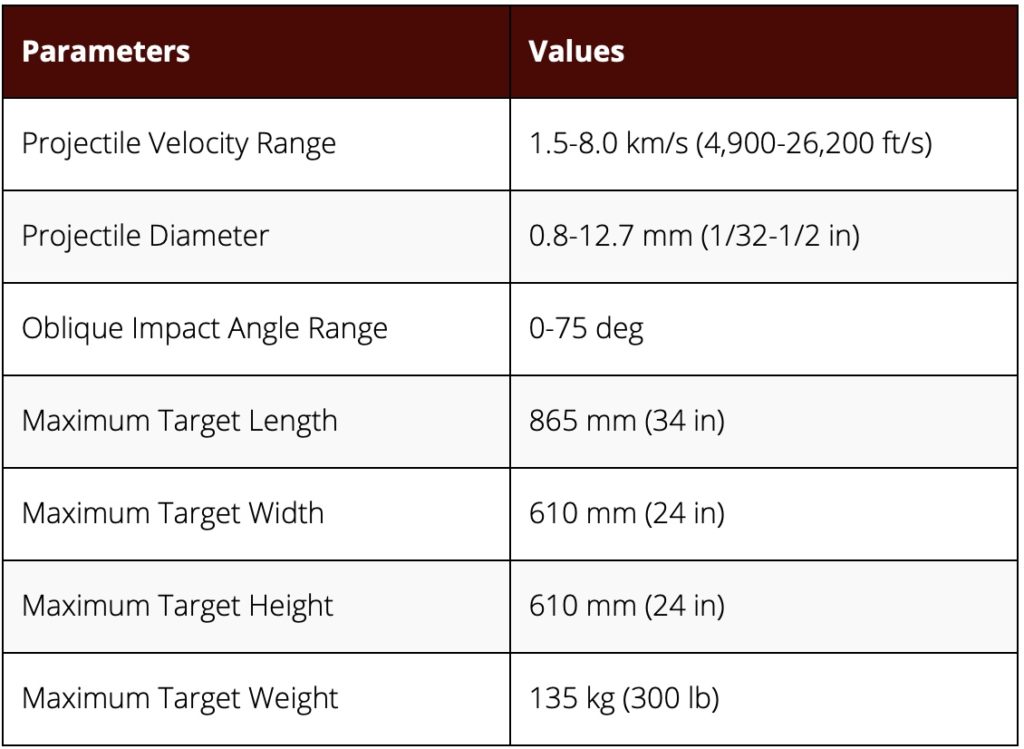

The Texas A&M University (TAMU) Hypervelocity Impact Laboratory (HVIL) is located at the Center for Infrastructure Renewal (CIR) at RELLIS campus of The Texas A&M University. The laboratory research is aimed at enabling unique high-rate materials characterization and multiscale numerical model development and implementation. The TAMU HVIL, operated by a team of distinguished researchers, provides a testbed for the development and tailoring of novel monolithic, layered, and architected structures comprised of polymers, composites, metals, ceramics, soft materials, gels, and geomaterials to mitigate HVI threats (e.g., hypersonic weapons, micrometeoroid/orbital debris, atmospheric reentry conditions). The laboratory currently houses a state-of-the-art two-stage light gas gun (2SLGG) capable of launching 0.8-12.7 mm diameter projectiles at velocities in the range of 1.5-8.0 km/s (3,355-18,000 miles/hr). Projectile materials currently include steel, aluminum, nylon, glass, polycarbonate, tungsten, and titanium. The modern and advanced facility at HVIL allows for targets of many sizes, shapes, and weights to be impacted efficiently and reliably at normal and oblique orientations. A brief description of the 2SLGG can be found here. The 2SLGG is currently equipped with a pair of laser intervalometers, an ultra-high-speed camera, a dual-head 450 kV flash X-ray system, high-speed Schlieren imaging, and novel particle tracking technology. Ongoing developments include advanced digital in-line holography diagnostics and modern target heating/cooling techniques. Future diagnostic equipment will include an additional high-speed camera(s), high-speed thermal camera(s), and a photon doppler velocimetry (PDV) system.

Quick Facts

2SLGG Specifications

Testing Specifications

Diagnostics and Testing Features

Ultra-high Speed Camera (up to 10 million fps)

- Frame rates up to 10 million fps

- 128 or 256 frames

- Down to 50 ns of exposure

- Accompanying high-power LED lights

Laser Intervalometer & Dynamic Delay Generator

- Main instrument for determining projectile velocity

- Velocity errors below 2 m/s at a projectile velocity of 8,000 m/s

- Highly reliable and repeatable measurements

- Rapidly adjustable and robust dynamic delay generator

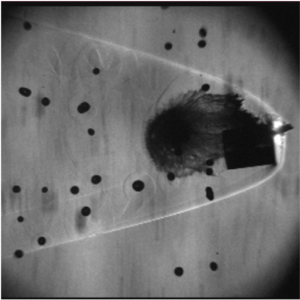

Flash X-ray System (450 kV)

- Pulsing voltages ranging from 150 kV to 450 kV

- Dual head setup allows for two spatially and/or temporally varied radiographs

- Pulse duration of 20 ns

Ultra-high Speed Schlieren Imaging

- Robust setup that uses high-speed camera (up to 10 million fps)

- Enables high-speed images of relative density gradients

- Allows for the in-situ characterization of shock-projectile, shock-particle/fragment, and shock-shock interactions

Particle Tracking

- Novel computational techniques enable the extraction of particle and flow field data

- Applicable to high rate, high temperature environments

- Provides size, position, velocity, temperature, and elemental composition of fragments produced during hypervelocity impacts

Single-Stage Launcher Modifications

- Impact research problems at lower velocities can be addressed

- Utilizes existing 12.7 mm bore

- Faster experimental throughput

See us in action

See a brief overview of our capabilities and how we perform hypervelocity impact experiments at the Texas A&M University (TAMU) Hypervelocity Impact Laboratory (HVIL).

Interested in HVI testing?

If you are interested in hypervelocity impact testing at the Texas A&M Hypervelocity Impact Laboratory, please complete the form here. A researcher will contact you within one week.

Affiliated Researchers

Waruna Kulatilaka

Justin Wilkerson

Brian Schuster

Jacob Rogers

Aniket Mote

Paul Mead

Khari Harrison

Dean Biava

Michael Rakoski

Max Murtaugh

Cullen Miller

Nathaniel Bass

Matthew Intardonato

Sidney Davis

Mikayla Wiest

Brynn Martin

Sarah Beth Ragan