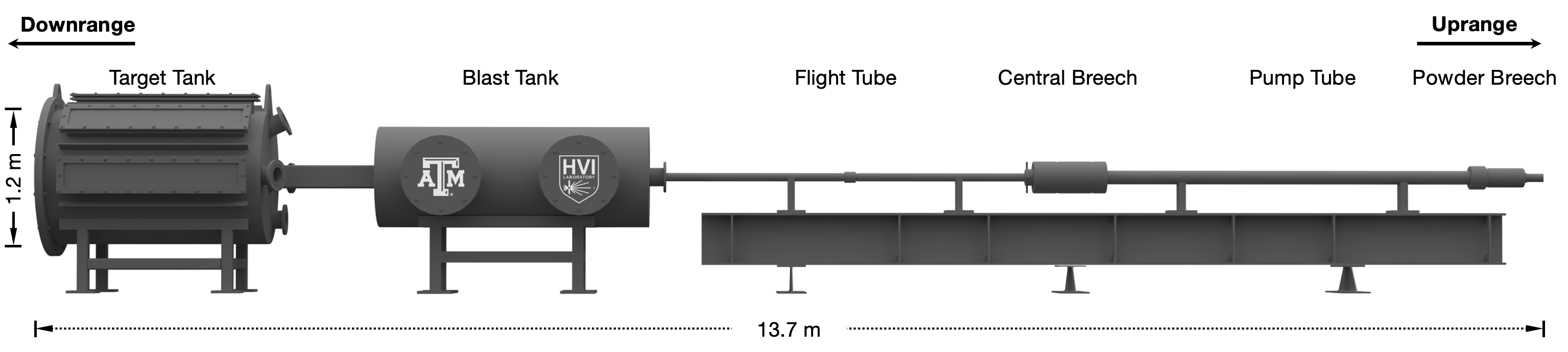

Firing System

The firing system consists of a remote initiation system (i.e., capacitor discharge) and a firing breech. The firing breech houses the small (< 2.0 g) primary charge (e.g., Hodgdons Triple Seven) used to ignite the secondary charge. Upon remote initiation, the capacitor discharges energy to the firing breech resulting in a magnetic pulse which thrusts the removable striker rod downrange. The striker rod impacts the primer on a Winchester 308 cartridge housed in the uprange side of the powder chamber, triggering the primary charge.

Powder Breech

Directly downrange of the firing breech, the powder chamber stores the secondary charge (e.g., Hodgdon’s H4831, IMR 4831), which is the first stage of the 2SLGG. The mass of this charge serves as the primary 2SLGG performance variable. Ignited by the primary charge, the secondary charge burns rapidly, releasing expanding gases into the pump tube.

Pump Tube

The pump tube houses the 2SLGG’s working gas (e.g., 140-280 psi of hydrogen gas) with a bore diameter of 1.75 inches. A remote operated gas handling system (i.e., valves, pressure transducers, and high-pressure plumbing/hoses) is connected here in order to remotely and efficiently pressurize the pump tube. The rapidly expanding gas resulting from the burning secondary charge forces an expendable polymer piston downrange, compressing the working gas into the central breech.

Central Breech

The central breech, located between the pump tube and the launch tube, hydraulically separates the high-pressure pump tube from the evacuated launch tube, blast tank, and target tank via a petal valve (i.e., pressure disc). Within the central breech, the 1.75 inch inner diameter of the pump tube transitions to the 0.5 inch diameter of the launch tube. The pressure of the working gas located on the downrange side of the compression piston increases rapidly until it reaches the burst pressure. Upon reaching said pressure, the petal valve ruptures, freeing a high-pressure jet of working gas into the launch tube.

Flight (Launch) Tube

The uprange end of the launch tube tightly houses the projectile package (i.e., plastic sabot and projectile) until the pressure disc ruptures. The high-pressure jet of working gas enters the 144 inch long tube, accelerating the projectile package downrange toward the blast tank.

Blast Tank

The blast tank is designed to prevent the sabot and gaseous debris from entering the target tank. The blast tank is 96 inches long with a diameter of 30 inches. Within the tank, there is a series of baffles that block any debris traveling downrange with the projectile package. Following the baffles, an apertured sabot stopping plate located on the downrange end of the blast tank catches the sabot, allowing only the projectile to enter the target tank.

Target Tank

The projectile concludes its downrange journey in the target tank. This A-36 steel tank has an inner diameter of 48 inches and a length of 72 inches. For impact event diagnostic instruments, there are five radially-oriented optical access ports that are 8 inches wide and 48 inches long. On the uprange end of the tank, there are three circular ports that each possess an inner diameter of 6 inches. All eight access ports are covered with o-ring-sealed polycarbonate windows that are secured with steel frames. Accompanying the optical ports, there are two additional ports used for evacuation and ventilation. The downrange end of the tank is a full-diameter hinged port used for loading/unloading target assemblies.

Fixturing

Target Fixture

Located in the target tank is a modular target fixture responsible for securing the target assembly during the impact event. The fixture is capable of anchoring up to 300-pound targets that are up to 34 inches in length and 24 inches in width and height. Oblique impacts up to 75 degrees are also possible using this fixture. The target fixture also rigidly holds the X-ray imaging plates and door protection system (DPS) during an experiment. A Whipple-shield-like structure, the DPS is a series of spaced steel plates that quickly stop downrange target debris and projectile fragments. This system enables testing with dense (e.g., tungsten) and long rod projectiles.

Diagnostic Fixture

To support a wide variety of diagnostic instruments, two modular fixtures have been designed and implemented. These stable fixtures stand 8 feet tall and can each support up to 1,000 pounds of diagnostic equipment. They are located on opposite sides of the target tank. In addition to capturing events from the side (0 and 180 degree) windows, events can be observed from the top (90 degree) window on the target tank by mounting cameras, lights, and other equipment to a cross beam that ties the two fixtures together. Currently, the diagnostic fixtures hold our flash X-ray heads at 45 and 135 degrees and our ultra-high speed camera + lights at a variety of positions, orientations, and configurations (e.g., back lighting, front lighting, Schlieren).