Principle Investigator(s) (PIs): Thomas Lacy, Jr.

Collaborators: Mike Mazzola, Charles Pittman, Jr., Dounia Boushab, Aniket Mote, Khari Harrison, Pedram Gharghabi, Juhyeong Lee

Funding Agencies: NASA

Summary

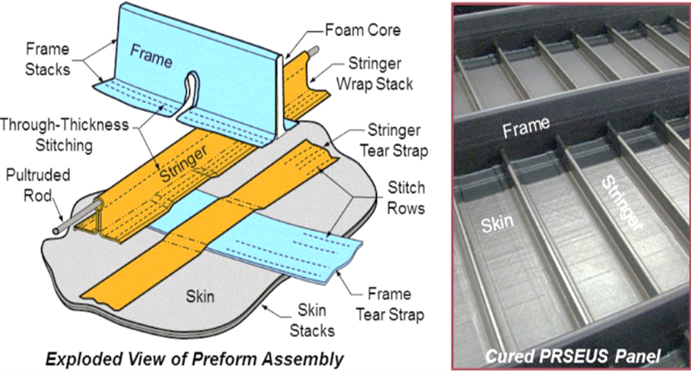

The lightning damage resistance of Pultruded Rod Stitched Efficient Unitized Structure (PRSEUS) panels was investigated experimentally. Two PRSEUS panels were subjected to standard Society of Automotive Engineers impulse current waveforms (consistent with actual lightning strikes) with 50, 125, and 200 kA nominal peak currents at a variety of panel locations. The outer mold line skin of one panel was lightly sanded to probe the influence of surface finish on lightning damage development. Lightning damage characteristics of the sanded panel were compared with those of a painted panel. The size of lightning-damaged regions in each panel increased as the peak current increased. The severity and size of lightning damage in the painted panel were much greater than that for the sanded panel due to paint’s greater dielectric properties. Lightning damage to PRSEUS panels manifests itself as (1) severe local damage occurring in the vicinity of the lightning attachment point and (2) surrounding widespread surface damage. The damaged regions were generally elliptical or semi-circular in shape and elongated along the outer lamina’s fiber direction. This is consistent with observations from unstitched carbon/epoxy laminates. Distributed widespread small-scale fiber damage displayed the same periodicity as the polyester warp-knit thread spacing used in the non-crimp fabric. A third painted PRSEUS panel was slotted and subjected to 50 and 125 kA nominal peak currents at mid-bay locations to investigate the effects of magnetically induced currents and lightning arc-expansion on widespread surface damage formation. The slotted panel experiments suggested that the observed surface damage is likely a result of the lightning arc-expansion. All of the lightning experiments demonstrated that the presence of through-thickness Vectran™ stitching dramatically reduced the development and spread of lightning damage. Moreover, PRSEUS panels exhibited markedly less lightning damage than comparable pre-impregnated laminated composites subjected to similar lightning currents. Nondestructive and destructive evaluation techniques were employed to assess the type and degree of through-the-thickness damage in PRSEUS and traditional laminated specimens. Phased array C-scan imaging of painted PRSEUS panels revealed that lightning damage (matrix decomposition, fiber breakage, delamination, etc.) was restricted to the upper skin-stack and that the size of the interply delamination was smaller than the observed surface damage. These results were consistent with microscopy images obtained from destructively sectioned panels. A series of stitched warp-knitted composite flat panels with different exterior lightning protection layers (i.e., copper mesh, graphene paper, and pitch carbon fiber paper) were fabricated and tested at 150 kA to assess protection layers effectiveness. A finite element model is in development to analyze and predict the lightning damage in stitched composite laminates. This research demonstrated that the use of stitched composites can enhance the lightning damage resistance of integrated composite aircraft structures.

Figure 2. A typical lightning strike test on a PRSEUS panel subjected to a nominal peak current of 200 kA.

Figure 2. A typical lightning strike test on a PRSEUS panel subjected to a nominal peak current of 200 kA.